High

Quality Machines

All the machinery and their facilities are listed below based on several levels of Research and Development. So, the details mentioned below are precise and up to date. Moreover, the operations that are not hosted by this concern can be still done through perfect outsourcing methods.

Offset Printing

Mitsubishi six color Inter-deck offset (Size: 30” x 40”) with UV printing, UV Coating, Aqua Coating and Tripp Off facilities. This offset belongs to Diamond series and so, high quality printing service is offered within a short period of time. Tripp Off services are offered both in Metalized and normal printed boards.

Cutting

ITOH type cutting machine (Size: 30” * 40” – 2 Nos.) for precise cutting and trimming. The accuracy achieved in this process serves as a backbone for our timely performance in offset printing. One machine completely satisfies offset requirements and the other is utilized for invitation manufacturing.

Screen Printing

Sakurai Screen Printing Machine (Size: 30” * 40”) for exclusive screen printing using water and UV based inks and Spot-UV coating operations. This process requires a pre-operation called Frame making which is also available indoors within the concern.

HOT-FOIL Stamping

Due to the increasing demand of foiling process from the invitation market, two technologies are hosted for Hot-Foil stamping. One is a cylinder technology for which two Heidelberg machines are possessed with variable sizes (25.25” * 18” and 25.25” * 35”). Second is a Platen Technology and the machinery that hosts this process is KLUGE EHD 13” * 19”.

Embossing

XINXI -102E model micro embossing machinery with Micro, Macro and Deep embossing in a single pass for reflection, knurling and deep embossing effects together.

Laser Cutting

Die-cutting with CO2 laser beam for fine and precise die-cutting and engraving. This technology works not only on papers and boards but also on fabrics and wooden surfaces.

Flatbed UV Printing

A "JUCOLOR" digital printing technology to print on any flat surface and some rotary surfaces with UV inks. Depending on the quality of surface, printing results are produced. Customized printing is done on any flat objects based on customer requirements.

Fiber Laser Marking

Small sized laser technology to produce more accurate engraving results on acrylic and many other surfaces including wood. The engraving results in this technology are substantially clear and legible to the readers.

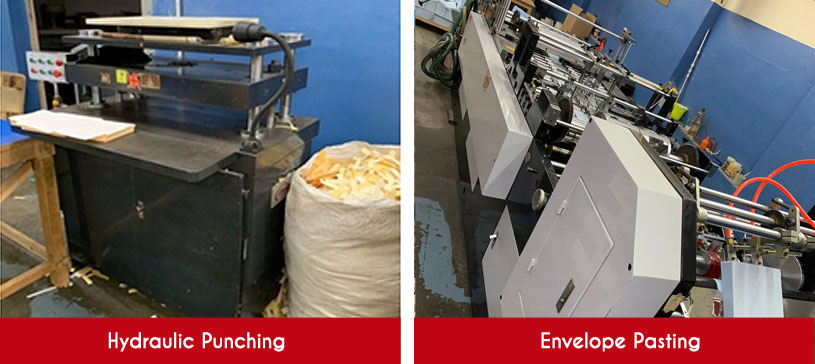

Hydraulic Punching and Envelope Pasting

Champion Envelope Pasting machine with counter for pasting envelopes (paper and board) after Hydraulic punching.

Shrink Packaging

EFK-250 C Shrink Packaging Machine for making economical and fine sealed packs of wedding invitations (Card, Cover and Inner) followed by tunnel wrapping.

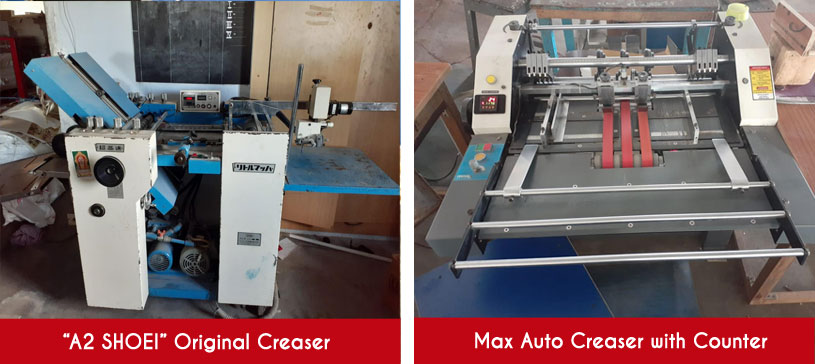

Creasing

One Max Auto Creaser with Counter for customized orders and One “A2 SHOEI” original Creaser with counting for high production.

Foiling and Embossing

Printech machine to achieve minute foiling and embossing results. The machine works with a pneumatic system at a slow speed to provide accurate registration results and takes the quality of products to the next level. (Size: 20x15 inches max.)